Cylinder filling – A project in standardisation

Linde has chosen Cryostar to accompany it in the ambitious project of standardising tools for cylinder filling facilities on a worldwide scale. In early 2013, Linde created its Performance Transformation Function to drive improvements in those areas considered essential for the development of the group.

One of the projects selected was to rethink the way in which industrial and medical gases were packaged, filled and handled. Cryostar was one of the filling companies consulted and evaluated. The study showed that Cryostar was the best partner for the development of such a large-scale project, requiring a continuous and lasting collaboration.

Cryostar, and more specifically Cryostar Automation, worked closely with a group of experts from Linde on this standardisation study. At the beginning, it was important to examine the specific issues and information gathered in different regions of the world and compare the ways in which they work and local statutory or regulatory conditions. This initial groundwork enabled us to produce a specifications document describing the future factory, whilst integrating all regional characteristics and guaranteeing a global concept.

It was at this crucial stage that the experience and expertise of Cryostar, associated with those of Linde Gas, were essential in defining the progressive yet standardised modular system.

For the second stage, we had to apply a number of our key competences to develop an innovative solution on a mechanical, electric and procedure control level. Risk assessment and HAZOP were conducted at that stage to ensure the plant is viewed as a complete system and not a compilation of various components. This overarching approach allows us to avoid the integration risks created by using several systems from different suppliers on the same location and therefore created a unified system.

Maximising production

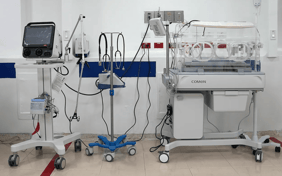

After one year of intensive work and the implementation of a specific test structure, Cryostar established two initial factories. These factories recently benchmarked by Linde achieve repeatable precise filling results more usually associated with Make to Order products, and beyond the levels typically seen in the industrial gas sector, for which Cryostar was initially consulted.

With the help of the customer, we developed the most advanced and safest system within this business for the benefit of operators and plant managers.

This first stage successfully achieved, Cryostar is now working on widening the range of inter-connectable modules and as a result is able to maximise production time and reduce the installation and onsite setting up period.

From now on, this method and the pre-configured factory can save a huge amount of precious time onsite. We are now able to set up a complete site between 30% and 50% faster than previously achieved. This method is being applied to different sized factories and, depending on client investment previsions, we are able to foresee and plan the material pre-fabrication and stock.

Advantages

At Cryostar we have found there are other inherent advantages linked to this standardisation practice, notably in the way in which maintenance is handled locally and also by reducing stocks of spare parts.

Following on from this way of thinking, all operators and those in charge of production at Linde are fully trained so they can work efficiently as soon as the factory is ready. South American, Chinese and European operators will all be using the same equipment, and these will regularly be updated with new developments by the company’s expert teams.

This example of cooperation clearly demonstrates the advantages of working alongside the client from the initial concept stage, in order to produce the best result for a specific need. This partner approach, already practiced within Cryostar Automation since 2008 with other gas-producing operators, is a fundamental element of the Cryostar culture – which we would like to promote and sustain.