MAN Energy Solutions to supply Air Products’ $4.5bn clean energy complex

Air Products has selected MAN Energy Solutions to supply six air-compressor trains for use in an air separation unit (ASU) in its $4.5bn clean energy complex in Darrow, Louisiana.

First announced in October 2021, the complex will produce more than 750 million standard cubic feet of blue hydrogen daily for Air Products’ customers to be transported along a 700+ mile pipeline on the US Gulf Coast.

Read more: Air Products announces $4.5bn blue hydrogen complex in Louisiana

The site will also produce blue ammonia for global hydrogen markets.

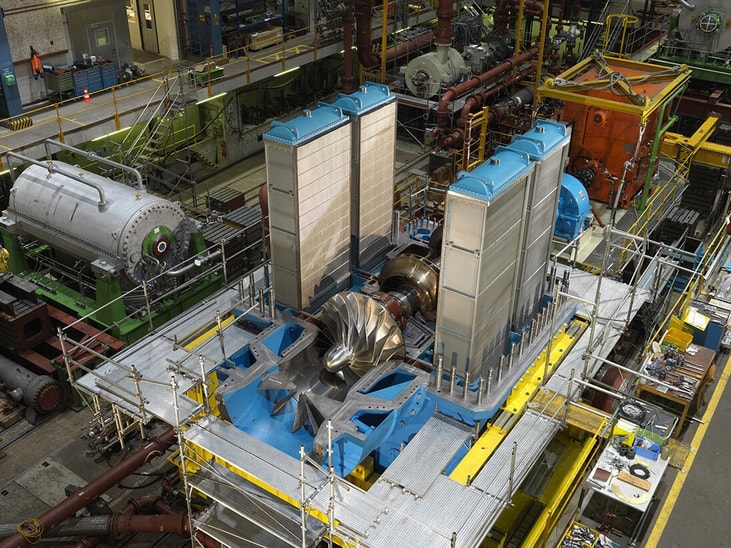

MAN’s air-compressed trains will be deployed at the core of Air Products’ ASU where air will be separated into its primary constituents of oxygen and nitrogen, both of which are needed for the production of hydrogen and ammonia.

The main air-compressor trains have three centrifugal stages and deliver more than 600,000 Nm3/h of air. The booster compressors are integrally geared types and have six (air) and five (nitrogen) stages, all with external intercoolers.

Zoran Paunovic, Head of Sales & Project Management, Air Separation at MAN Energy Solutions, said the air-compressor trains reduce energy consumption and minimise environmental impact.

MAN will supply two types of compressors to the Air Products clean energy complex.

Paunovic explained, “The RIKT compressors feature an innovative impeller design that increases energy efficiency while reducing wear and tear on the unit. This design improves the compressor’s overall performance and extends its service life, providing reliability and lower maintenance costs, combined with a very compact design and small footprint.”

“In contrast, the RG compressors are ideal for reaching different high-pressure demands by using different shaft speeds to run each impeller within the optimum efficiency point. In this way, energy consumption can be reduced while reaching maximum capacity.”

Approximately 95% of the CO2 generated at Air Products’ site will be captured, compressed, and transported safely by pipeline to multiple inland sequestration sites located along a pipeline corridor extending up to 35 miles to the east of the new production facility.

Air Products will provide all of the complex’s products – blue hydrogen and co-products (liquid nitrogen, liquid oxygen and liquid argon) – to customers in the US and around the world.

CO2 Summit 2023

Shortages and sourcing challenges are the headline stories everyone’s talking about in CO2 supply. But the whole carbon dioxide value chain is transforming – as this story itself demonstrates.

Applications are not only emerging and evolving but demanding more of the industry and its sourcing too. That calls for new thinking in CO2 storage and distribution, but it also raises questions over the tracking and management of supply chains. How we see CO2 is changing, shifting from waste disposal to a value chain in its own right. This will see the tonnage utilisation of CO2 evolve beyond recognition.

Join gasworld this September as our North American CO2 Summit 2023 assesses the threats, challenges and opportunities ahead in carbon dioxide – how we find it, source it, purify it and deliver it. Learn about the changing face of CO2; the opportunities in direct air capture (DAC); supply chain strategies; carbon credits and legislation; and so much more.

Tickets are selling fast and sold-out early last year, so book your place now. For more information and how to attend, visit https://gasworldconferences.com/conference/north-american-co2-summit-2023-indianapolis/