UB awarded $1.8m to develop carbon capture technology

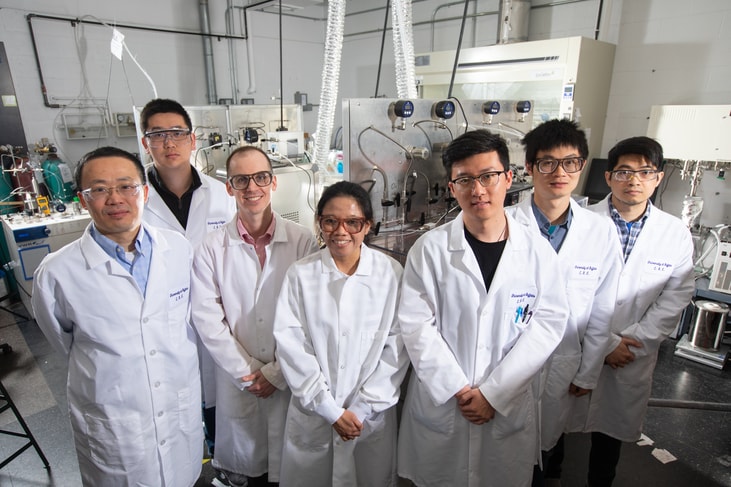

Researchers from the University of Buffalo have received $1.8m funding to develop its carbon capture technology.

The multi-institution project is developing membranes that can separate CO2 from other gases, a technology that has the potential to be installed by factories and power plants to cut down the amount of released carbon.

The $1.8m funding includes $1.2m from the US Department of Energy (DOE) and $600,000 from Empire State Development’s Division of Science, Technology and Innovation (NYSTAR).

... to continue reading you must be subscribed