ASCO delivers dry ice blasting technology to ABB product development

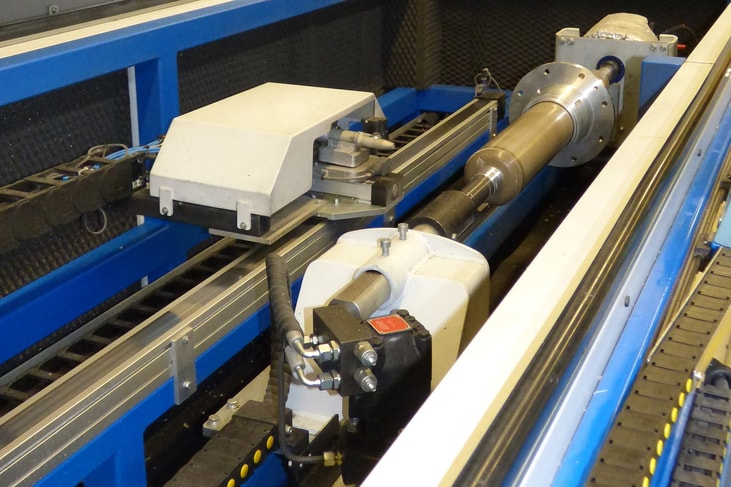

Carbon dioxide (CO2) solutions provider ASCO CARBON DIOXIDE LTD helped technology innovator ABB Group to develop a new product with its dry ice blasting technology.

As a leading supplier of energy and automation technology, ABB supplies systems and solutions for industrial companies and public utilities. The company employed Switzerland-based ASCO’s dry ice blasting machine for automated mould cleaning during a recent product development process.

During ABB’s product development, its team battled with residues of release agent on the casting mould of its test piece during silicon removing processes. As a result, a primer could not adhere to the test piece and halted subsequent production steps.

... to continue reading you must be subscribed