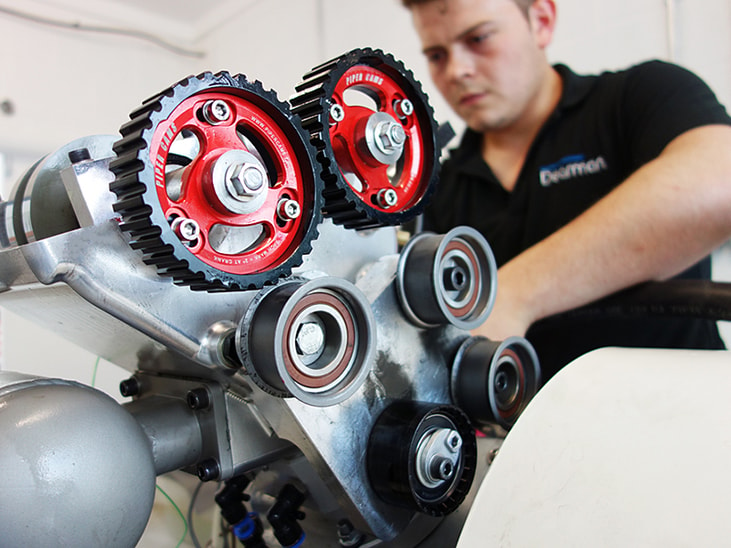

Acquisiton of CNC milling machine boosts Dearman’s in-house prototyping abilities

UK-based clean cold technology company, Dearman, has acquired a computer numerical control (CNC) milling machine to increase its in-house prototyping capability.

The Haas UMC 750 is now operating at the Dearman Clean Cold Technology Sector in Croydon, enabling the business to manufacture customised components for its technology onsite.

Dearman believes this will significantly reduce its manufacturing costs and lead times.

Nick Owen, Dearman’s Chief Technology Officer, outlined, “The CNC machine has enabled us to take control of the whole engineering process, and the capacity to machine parts to our own specification means that we have been able to accelerate our projects.”

... to continue reading you must be subscribed