Adopting additive manufacturing

Companies putting manufacturing at the heart of their business are under mounting pressure, both from global competition and the rapid rise in technological advancements that are changing the way goods are manufactured.

With mass production having largely shifted to developing economies, Western companies are moving towards lower volume production of high-added value, innovative, customisable and more sustainable products. They also continue to seek out ways to improve cycle times, reduce waste and maximise work flow.

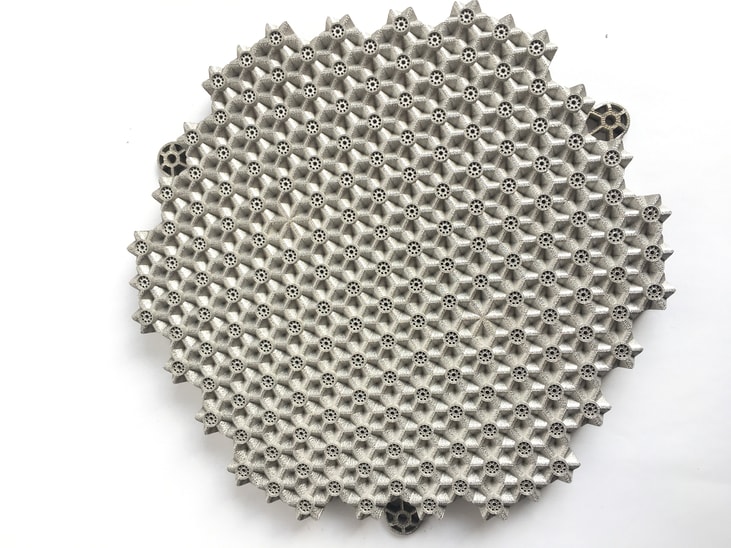

To compete in this new environment, manufacturers have sought new fabrication approaches to support economic low volume production. One such emerging technology is Additive Manufacturing (AM). Capable of producing fully dense components layer by layer from computer aided 3D modelling, the technology removes many of the limitations of manufacturing techniques based on traditional subtractive methods.

... to continue reading you must be subscribed