Afrox packages plasma technologies for lower running costs

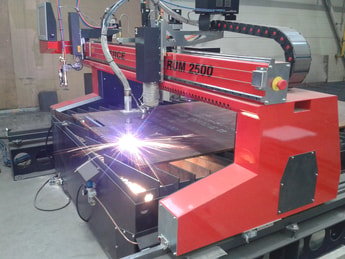

Afrox, a member of the Linde Group, has coupled Pierce’s flexible range of precision CNC profile cutting tables with Thermal Dynamics’ water mist plasma (WMS) technology.

This coupling offers an excellent combination of features for metallic materials, such as stainless steel, aluminium, copper and titanium.

The Thermal Dynamics range includes the Standard Cutmaster A series, the Auto-Cut XT series and the Ultra-Cut XT.

The Standard Cutmaster A series is a light duty cycle, entry-level air plasma system, with a cut quality of up to 120 Amps and ideally suited for heavy plate cutting applications.

... to continue reading you must be subscribed