Air Liquide inaugurates HyBalance

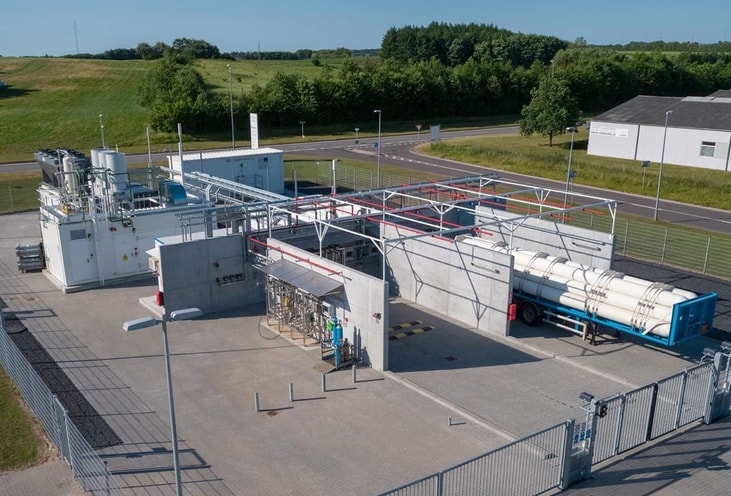

One of Europe’s most advanced hydrogen (H2) facilities has been inaugurated today in Denmark.

Under the coordination of Air Liquide, the HyBalance project brings together a group of partners – Hydrogenics, LBST, NAES Energy, and Hydrogen Valley – for the construction of one of the largest carbon-free H2 production units in Europe.

The H2 is produced from water electrolysis, enabling the storage of renewable electricity from wind turbines. The electrolyser, with a capacity of 1.2MW, enables the production of around 500kg of H2 a day without releasing CO2. It helps balance the grid, which is essential for the stability in electricity systems.

... to continue reading you must be subscribed