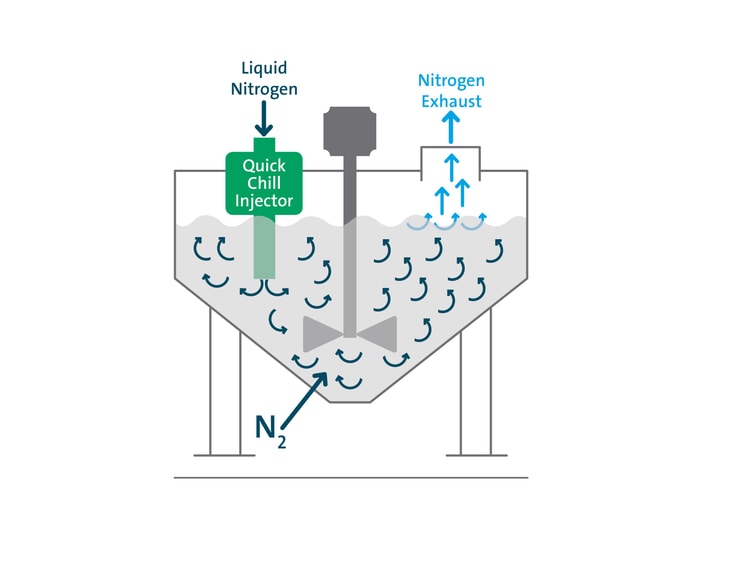

Air Products launches Freshline QuickChill Injector for rapid chilling

Air Products has launched its latest innovation in cryogenic food processing solutions, the Freshline® QuickChill™ Injector.

The QuickChill Injector allows food manufacturers to chill sauces and liquids in minutes through the rapid cooling power of liquid nitrogen whilst complying with USDA cooling guidelines that require cooked liquid products to be chilled to 4°C (40°F) within five to six hours.

The unit comes in a standard model that can be fitted to a variety of new or existing kettles and vessels, eliminating the need to invest in additional kettles, equipment or floor space.

... to continue reading you must be subscribed