Airgas Experts to Demonstrate welding and fabrication technologies at FABTECH 2015

Airgas, Inc. has announced that its Advanced Fabrication Technologies group will attend and exhibit at FABTECH 2015 in Chicago, Illinois next week.

Held from 9th – 12th November, FABTECH will see Airgas’ welding and fabrication experts on-hand to demonstrate and discuss the innovative systems available for rent or lease through its Red-D-Arc Welderentals company.

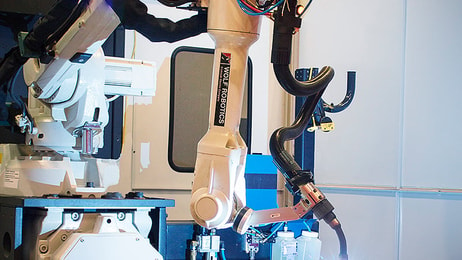

The exhibit will also demonstrate a live robotic system able to cut with plasma and weld, as well as orbital welding and end-prep equipment and accessories.

Airgas and Red-D-Arc representatives will be on-hand to discuss these technologies, plus provide an overview of vending equipment and strategies that help its customers control the consumption of many consumable products.

... to continue reading you must be subscribed