AMETEK Land Borescope (NIR-B) 3XR obtains CSA certification

AMETEK Land has secured CSA certification for its Near Infrared Borescope (NIR-B) 3XR for use in hazardous locations in the US and Canada.

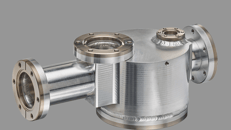

The NIR-B 3XR, which was launched to the industrial gas sector in 2016, delivers continuous reformer tube wall temperature (TWT) measurement and furnace optimisation and monitoring, allowing highly accurate temperature point data to be measured, stored and trended over the lifetime of the furnace.

CSA Certification means that NIR-B 3XR meets the requirements of regulatory authorities in the US and Canada at federal, state and local levels. Along with its previous ATEX and IECEx certifications, the NIR-B 3XR can be used in most countries around the world, making it much easier for operators to specify a single technological solution for high-accuracy, safe, non-contact temperature measurement.

Thomas Fortinberry, Business Development Manager, Industrial Gas, for AMETEK Land, commented, “We secured ATEX and IECEx certification when we launched the NIR-B 3XR, so it is great that we can now add CSA Certification to its list of accreditations.”

... to continue reading you must be subscribed