An interview with Gas Sensing Solutions

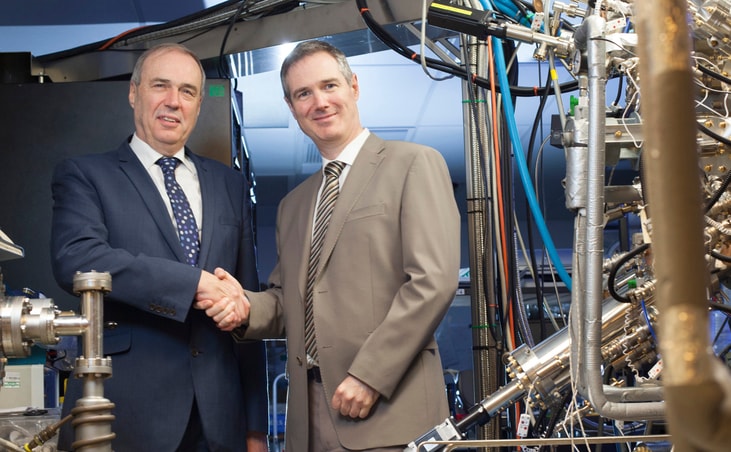

Gas Sensing Solutions (GSS), designer and manufacturer of low power, high speed Non-Dispersive Infrared (NDIR) carbon dioxide (CO2) gas sensors, appointed a new CEO back in August 2016, with the aim of scaling the business, building on the platform of technology and products to drive its global expansion.

GSS was founded in 2006 by Alan Henderson. Henderson was then joined immediately by Calum MacGregor, the current Chief Technology Officer (CTO).

The first five years of operation were spent developing the technology and creating GSS’s first products. During these primary years, the company was surviving through external investors, many of whom were acquaintances of the well-networked Alan Henderson.

... to continue reading you must be subscribed