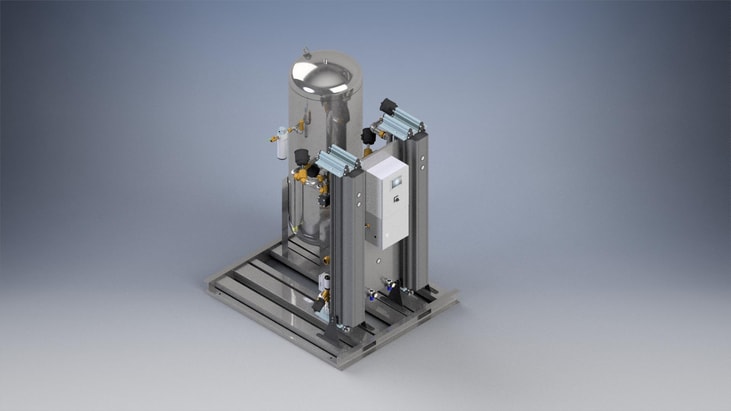

Applications focus: Nitrogen generation and nitrogen gas in laser cutting processes

Metal cutting processes with laser technology are more efficient and successful methods in many aspects compared to other known methods. The laser cutting method is frequently preferred in the industry in order to achieve high surface quality, precise and fast cutting.

In principle, laser cutting is based upon local combustion, melting, and evaporation of the material by sending focused and amplified rays to the surface to be cut. The directed strong rays break the bonds of the material and thus, the cutting process takes place.

There are some parameters in laser cutting technology that increase production efficiency and directly affect product quality. One of these parameters concerns the used gases that directly contact with the material during the cutting process. Various gases are used in the laser cutting process, depending on the material type, in order to remove the melted material from the surfaces and to achieve better cutting edges. Burrs are removed from the cutting area by using pressurised nitrogen gas (on average 12-20 barg) by creating a mechanical force. The quality of nitrogen gas that contacts with the cut material is very important. If the percentage of oxygen as an impurity in nitrogen gas increases, the material is oxidised, and the cutting quality deteriorates.

... to continue reading you must be subscribed