Atlas Copco and Processing Division to introduce new technology at Gastech

Atlas Copco and Processing Division will introduce its new cryogenic high-pressure BOG handling technology at Gastech 2019.

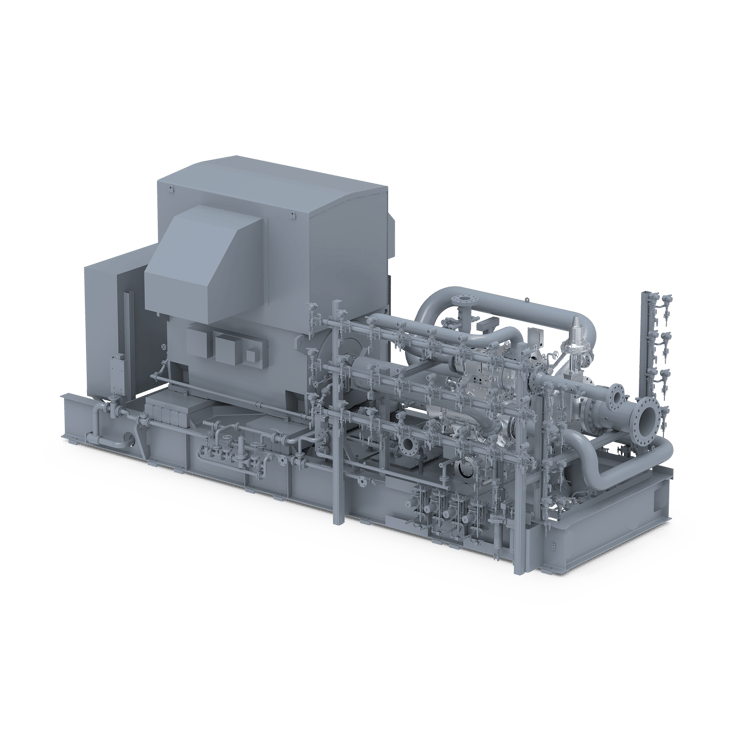

Using cryogenic low-pressure boil off gas (BOG) and fuel gas boosting reference machinery, Atlas Copco Gas and Process has engineered a compressor which handles cryogenic high-pressure BOG applications.

The machine is the first to combine two cryogenic and four warm stages on a single gearbox and skid, allowing for a small, more efficiently operating machine.

... to continue reading you must be subscribed