Atlas Copco presents new pumps at Glasstec 2018

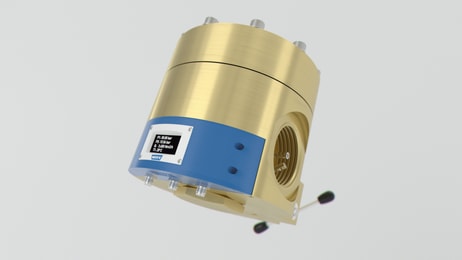

Atlas Copco presented its new variable speed drive vacuum pump series GHS 3800-5400 VSD+ at Glasstec 2018 in Düsseldorf.

The GHS VSD+ series was developed according to Atlas Copco’s proven philosophy and is therefore designed as a durable plug-and-play system in a single housing.

“The energy- efficient units deliver higher volume flows per hour and kilowatt power consumption than vacuum pumps with comparable performance,” explained Christoph Angenendt, Communications Manager Industrial Vacuum at Atlas Copco.

... to continue reading you must be subscribed

![Atlas Copco_HP BOG[1]](https://www.gasworld.com/cdn-cgi/image/width=231,height=130,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/atlascopco_hpbog1_804720.png)

![Atlas Copco_HP BOG[1]](https://www.gasworld.com/cdn-cgi/image/width=462,height=260,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/atlascopco_hpbog1_804720.png)