Leybold uses augmented reality to make maintenance and repairs easier

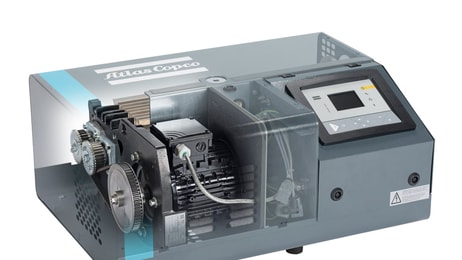

Leybold GmbH, a German division within the Atlas Copco Group, is the first vacuum pump manufacturer to test the diverse application possibilities of augmented reality (AR).

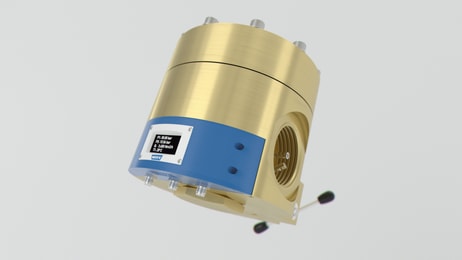

While executing tasks, service technicians obtain useful additional information and graphical documentation, partly in 3D. Leybold plans to extend the scalable AR apps to other product areas such as training, repair and maintenance purposes.

Since 2016, Leybold has been using the advantages of AR for the dry pumping system DRYVAC. The added benefits have prompted Leybold to extend AR to other areas.

... to continue reading you must be subscribed

![Atlas Copco_HP BOG[1]](https://www.gasworld.com/cdn-cgi/image/width=231,height=130,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/atlascopco_hpbog1_804720.png)

![Atlas Copco_HP BOG[1]](https://www.gasworld.com/cdn-cgi/image/width=462,height=260,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/atlascopco_hpbog1_804720.png)