Best practices for delayed labelling

With all the bizarre news coverage we see on TV today, don’t be surprised if US businesses continually stop, start, and stagger through the remainder of the year. Given the erratic trends in the stock market, the recent surge in bankruptcies, ongoing sporadic Covid-19 virus outbreaks, brewing tensions between the US and China, and the upcoming presidential election, it doesn’t take long to figure out that we all need to create well thought-out backup plans to adapt to these turbulent times.

One question you might be asking yourself… how could these events potentially impact my business?

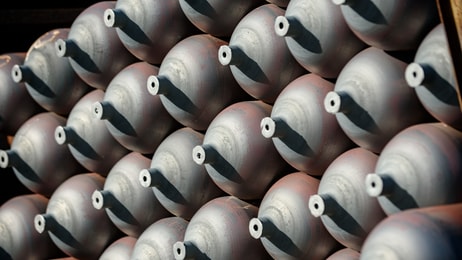

One possible answer? Supply chain. Even with the most common fundamental approach to these crazy times, executive management can still get blindsided when production lines suddenly come to an abrupt halt due to a disruption in supply chain.

... to continue reading you must be subscribed