Parker Bestobell Marine contracted to supply first globe valves with electric actuators for LNG vessels

Valve specialist Parker Bestobell Marine has secured another major new order for its cryogenic valves, supplying the first ever globe valves featuring electric actuators to liquefied natural gas (LNG) carriers.

The order for Daewoo Shipbuilding & Marine Engineering (DSME) in South Korea will see the UK-based business supply the cryogenic valves for three new vessels in the Yamal series of Arc-7 ice-class LNG carriers.

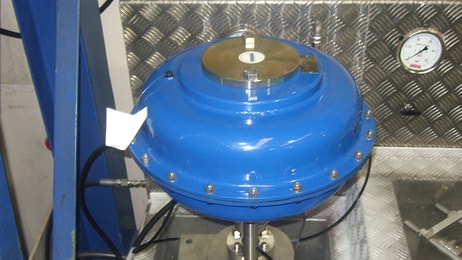

For the project, Parker Bestobell had to reinvent its valves design in order to withstand the extreme Arctic operating conditions. As such, Bestobell replaced its hydraulic oil actuators with electric actuators to ensure efficient operation and avoid viscosity issues in the Baltic temperatures.

... to continue reading you must be subscribed