Burch Tank & Truck Inc. expands precision cutting capabilities

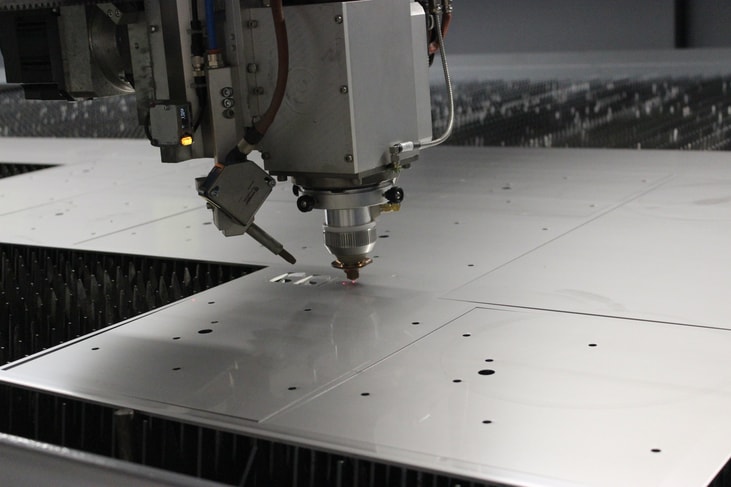

Burch Tank & Truck Inc., US-based bulk tank trailer and equipment manufacturer, has added a 20’ fibre laser cutter to its list of current available equipment.

Fibre lasers have always been known to provide highly accurate cuttings while operating more efficiently with lower costs associated to the product. They can also cut thin metals three times faster than CO2 laser systems.

Burch Tanks fibre cutter has an 8’ x 20’ double bed and can cut parts ranging from small, intricate pieces to large items. This laser cutter can handle up to ¾” carbon steel, up to 7/16” stainless steel and aluminium alloys, and up to ¼” brass. It allows unique materials, that were previously difficult to cut, to be quickly and precisely cut.

... to continue reading you must be subscribed