Cambridge Sensotec explains sensors in Rapidox range

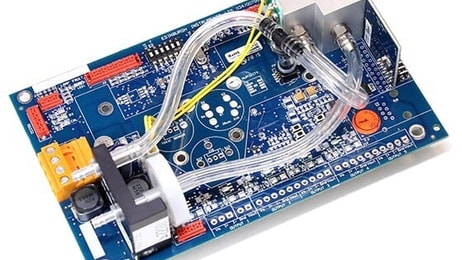

Cambridge Sensotec, experts in gas analysis, have been producing the Rapidox range of gas analysers for over 17 years.

Dynamic and flexible, the company initially specialised in oxygen (O2) analysis, however expanded into multiple gases to suit customer requirements and application demands.

The Rapidox 1100 and Rapidox 2100 range of O2 analysers are particularly suitable for applications such as inert gas blanketing, additive manufacturing, glove boxes, metal heat treatment and research and development projects.

... to continue reading you must be subscribed