CarbonCure Consortium advances CCU

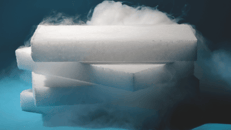

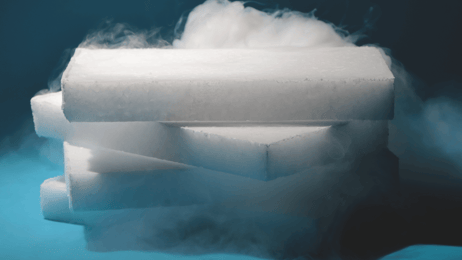

CarbonCure Technologies (CarbonCure) led a team of five companies to demonstrate the world’s first integrated carbon dioxide (CO2) capture and utilisation (CCU) from cement for concrete production in January 2018 – a major milestone for the company.

This project built upon previous cement plant CO2 capture demonstrations and was the first project to collect cement kiln CO2 for subsequent utilisation downstream in concrete production and construction.

The project demonstrates a turn-key solution for the cement and concrete industries that could create an opportunity to profitably capture and convert cement production CO2 emissions into value-added concrete for construction projects. Specifically, CO2 emissions from the Argos Roberta cement plant near Calera, Alabama, were captured by Sustainable Energy Solutions’ (SES) Cryogenic CO2 Capture technology, transported by Praxair and reused in Argos’ Glenwood (Atlanta) concrete operations equipped with CarbonCure’s CO2 utilisation technology. This concrete manufactured with the waste CO2 from the Argos Roberta cement plant was then used in a local construction project in the greater Atlanta area. Design partners and fellow members of CarbonCure’s Carbon XPRIZE team such as LS3P Architects, Uzun + Case Structural Engineering, and Walter P. Moore Structural Engineers complete the end to end integrated solution by creating demand for CarbonCure concrete products in the marketplace. Kline Consulting oversaw the commissioning and reporting of the industrial demonstration.

... to continue reading you must be subscribed