CarbonCure: Policy is needed to make the most of CO2 in the concrete industry

“We need policy makers to make policy, to reduce barriers so we can take carbon dioxide (CO2) and reuse it in a beneficial way to create value.”

Those were the words of Dean Forgeron, Senior Vice-President of Engineering and System Development at CarbonCure Technologies at CarbonCure, when he spoke on the first part of gasworld TV’s two-part CO2 series on Friday (23rd July).

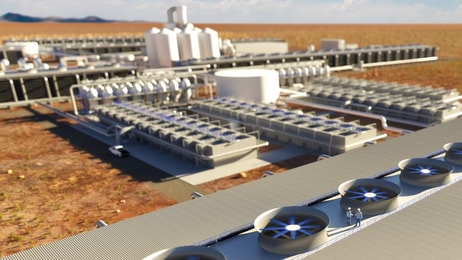

Headquartered in San Francisco, CarbonCure develops CO2-utilisation technologies that consume industrial CO2 to manufacture valuable products to help decarbonise the concrete industry.

Informing gasworld TV on the progress the company has already made, Forgeron, said, “We’ve installed in about 330 plants to date and by the end of next month will be over 400 plants globally. Currently in about five continents, and when we enter 400 thresholds, we should be in seven continents – so we’re really starting to expand globally.

... to continue reading you must be subscribed