Celeroton launches turbo compressors for nobile and inert gas applications

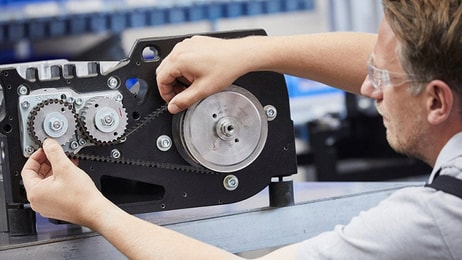

Swiss high-tech business Celeroton has launched a new turbo compressor series CT-NG specifically optimised for noble and inert gases.

The modular CT-NG platform covers different gases, such as argon, neon, nitrogen and gas mixtures (e.g. with a noble gas as a carrier gas), by making appropriate aerodynamics and gas bearing adaptions.

The sealing concept of the compressor minimises contact of the process gas with (so called wetted) materials within the compressor and therefore works fully without the need for rotating sealings.

... to continue reading you must be subscribed