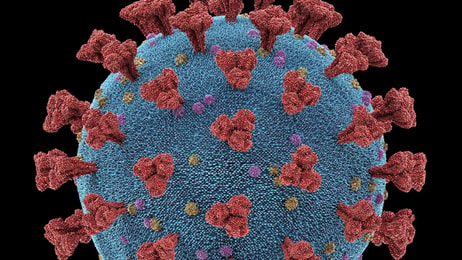

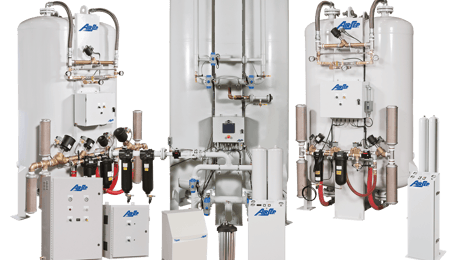

Chart ramps up production of critical care products

Chart Industries has ramped up production of specific critical care products in the US by more than 60% and in the Czech Republic by 50% to meet an increased demand for its oxygen storage and distribution equipment as the number of Covid-19 cases grows around the world.

The cryogenic equipment manufacturer fabricates critical care products in six global strategic locations: Georgia and Minnesota in the US, Italy, France, India and China. All governments in these locations have deemed Chart as an “essential” business to produce medical and power generation products.

Bob Knight, Application Development Manager, told gasworld, “The Covid-19 virus creates respiratory issues and high oxygen demands for many patients. Of significant note, is the oxygen flow and pressure requirements of the respiratory equipment needed for critical patients. Most of these respirators cannot be supplied by small oxygen concentrators and require a source of liquid oxygen.

... to continue reading you must be subscribed