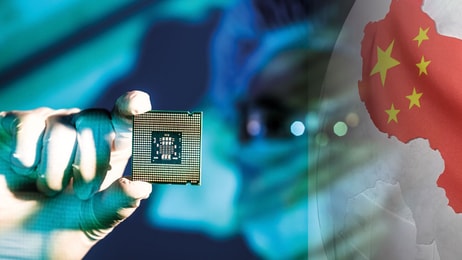

China rapidly moving to the forefront of the global electronics sector

In a market benefiting from a welcome wave of evolution over revolution, there is still one aspect of the global microelectronics business that is the subject of transformation – China continues to rapidly rise to the forefront of electronics sector hubs.

SEMICON West 2017 was held in San Francisco (US) earlier this month (July) and provided a wealth of key takeaways for those in the business of electronics and materials supply, including the transition from 2D to 3D NAND, the rise of the Internet of Things (IoT), and the EUV technology roadmap.

For Dr. Paul Stockman, Head of Market Development at Linde Electronics, the sector’s continuous innovation rather than nervous anticipation of the next big thing was arguably the biggest highlight. This, he enthused, is bringing about a renewed sense of optimism and confidence in the industry.

... to continue reading you must be subscribed