Linde and BASF complete successful CO2 capture pilot project at NECC in Alabama

The Linde Group and BASF have successfully completed a joint pilot project to improve the capture of carbon dioxide (CO2) from flue gas at a coal fired power plant at the National Carbon Capture Centre (NCCC) in Wilsonville, Alabama.

By pooling their technologies, the industrial gas giant and the world’s leading chemical company captured more than 30 tonnes of CO2 per day at a capture rate of more than 90% in the Wilsonville project. In addition, the purity of the captured CO2 was more than 99.9%.

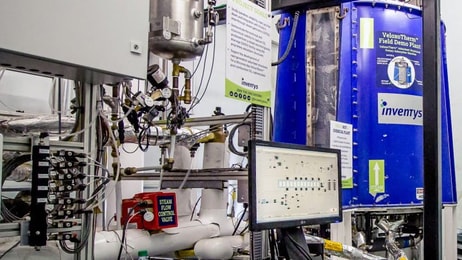

The technology used during the scheme combined Linde’s CO2 capture process and engineering with BASF’s advanced aqueous amine-based solvent and process technology. Operating at the NCCC facility for more than 1,200 hours, the pilot plant withstood higher regeneration pressure of 3.4 bar absolute.

... to continue reading you must be subscribed