CO2-free fermentation sees fruition as demand increases for low-carbon biofuel

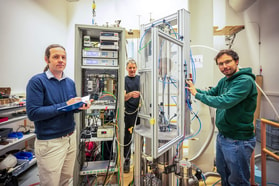

Researchers at the National Renewable Energy Laboratory (NREL) have received a nearly $3 million award from the U.S. Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E) to study a biorefining process that plans to increase fuel yields and recycle carbon dioxide (CO2).

As demand increases for a low-carbon biofuel, NREL have partnered with the University of Oregon, Genomatica and DeNore to lead a project that aims to utilise electrochemistry in the sugar fermentation process to produce lipids used to create biofuels.

During the fermentation processes that use biomass to make renewable diesel and sustainable aviation fuel (SAF) as much as one-third of the carbon in sugar is lost as CO2. This project aims to eliminate this loss, which will not only reduce the amount of CO2 emitted into the atmosphere but will also allow retention of as much carbon as possible in the fuel itself, thereby increasing yields.

... to continue reading you must be subscribed