Cold Jet to showcase MicroParticle technology at NPE2018

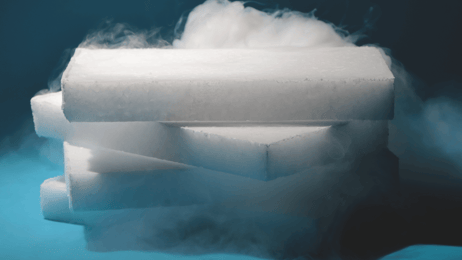

Cold Jet®, manufacturer of high performance dry ice cleaning and production equipment, will demonstrate its MicroParticle technology at NPE2018.

MicroParticle technology is used heavily in the plastics industry to clean molds, deflash and deburr parts, and for surface preparation prior to painting. The technology allows companies to clean molds at operating temperature and in place and does not generate any secondary waste or leave residue behind.

Cold Jet’s patented MicroParticle technology shaves dry ice into sugar-sized particles. This allows more media to strike the surface per second than traditional methods, resulting in an increased coverage area and a faster and more even clean.

... to continue reading you must be subscribed