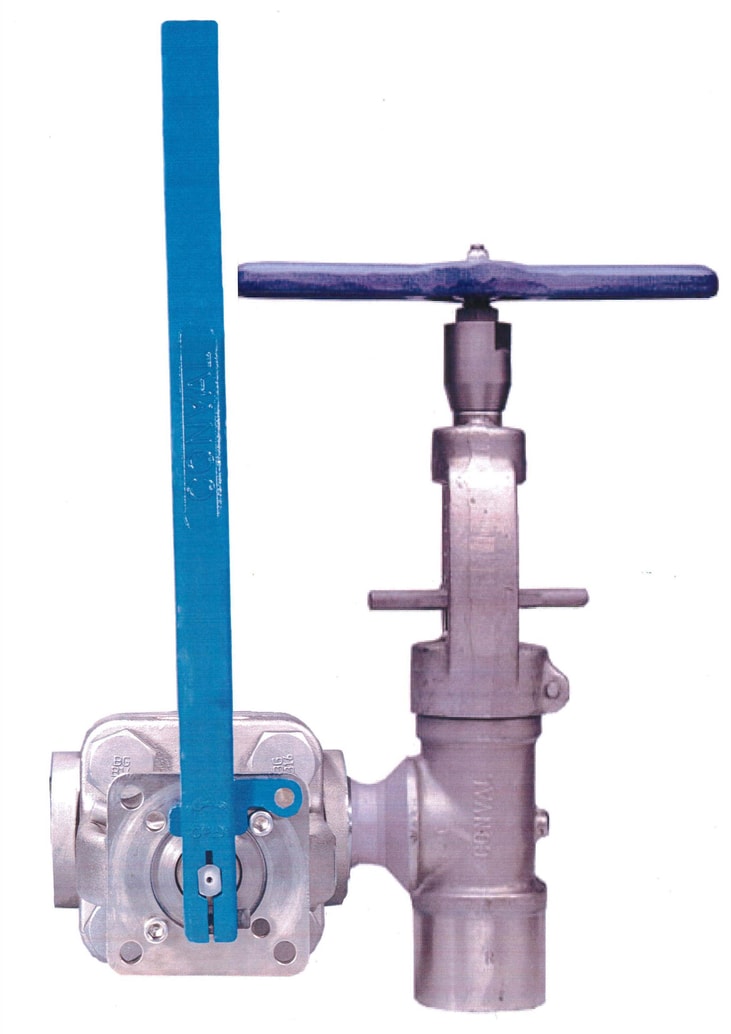

Conval CLAMPSEAL tandem blowdown service valves

Conval, a global leader in high-performance valves headquartered in Connecticut, offers CLAMPSEAL® blowdown service valves to provide necessary control for continuous or tandem boiler or turbine blow down and bottom blow-off service.

For continuous service, blowdown valves are available in ¾” through 4” sizes with butt or socket weld and flanged ends, in ASME/ANSI Class 900 through 4500. Standard materials are Low Alloy SA 182-F22, SA-182-F91 or SA-105. Specials are available upon request.

For tandem service, blowdown valves are available in ¾” through 4” sizes with butt or socket weld and flanged ends, in ASME/ANSI Class 900 through 4500. Standard materials are carbon steel A105, low alloy F22 or F91.

... to continue reading you must be subscribed