Cryonorm Systems LNG filling stations

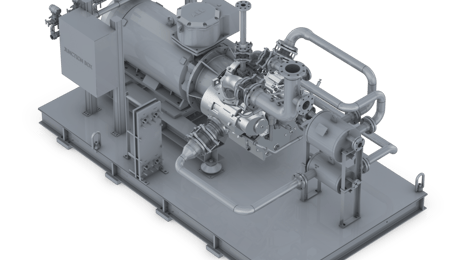

Cryonorm Systems, based close to Amsterdam, The Netherlands – leading designer and supplier of tailor made cryogenic systems and vaporisers – believes that natural gas (LNG) could form a bigger part of the transport energy mix as a lower-carbon fuel.

Used in trucks delivering goods, LNG has the potential to offer fuel cost savings when compared to conventional diesel. It can also reduce sulphur emissions, particulates and nitrogen oxides (NOx), and help reduce greenhouse gas emissions from production to use. Burning LNG in spark-ignited engines is also quieter than burning diesel in combustion engines. This means LNG-fuelled trucks can operate longer under noise restrictions, for example when delivering to supermarkets in residential areas.

The growing potential for gas fuelled vehicles is Cryonorm’s main driver to develop a standard range of LCNG filling stations. In 2013 CryoTek Services was started in the same group to handle all the on-site works, such as installation, commissioning, start-up and maintenance services. Since then, CryoTek Services has signed contracts for the maintenance and after sales services of Cryonorm LNG systems including a special contract with the Linde Group for cryogenic tank refurbishment premises.

... to continue reading you must be subscribed