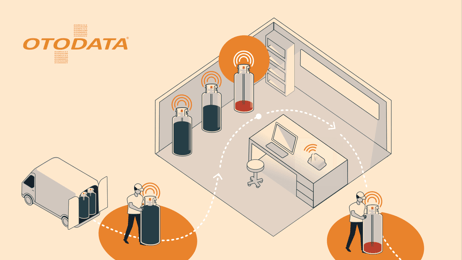

Cylinder management – Siargo offers ultimate solution for gas cylinder management and logistics

California-based MEMS mass flow sensing products manufacturer Siargo has released a new product line of innovative connected gas usage meters for gas cylinders based on its proprietary microelectromechanical system (MEMS) mass flow sensing technology with wireless connections to the cloud computing platforms of the Internet of Things (IoT).

The production and distribution of gas in cylinders is a multi-billion dollar business. It serves the markets from industrial, medical, to residential utilities. Managing the logistics of producing and distributing them is a huge challenge. For example, residential energy gas cylinders are still the best of the choices for remote countryside where the pipeline construction is too costly.

An empty gas cylinder can be a major interruption to daily life, while for medical customers, it can be a life support issue. Medical gas cylinder manufacturers in a big city often struggle to schedule regular and irregular dispatches to the customer requirements due to inaccurate statistics or unexpected events, including city traffic. For manufacturing industries, insufficient gas can interrupt production and cause significant economical loss.

... to continue reading you must be subscribed