Dearman testing new cryogenic pump

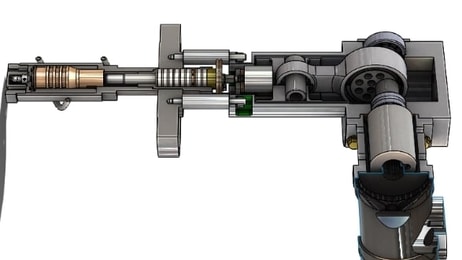

Dearman is testing a new cryogenic pump developed in partnership with venture engineering specialists Productiv as part of an environmental transport programme.

The clean cold company said it had successfully delivered a prototype of the important component for the Dearman-Hubbard TRU back in January.

Dearman and Productiv’s green transport programme reaches key milestone

The pump, part of the £15m Cryogenic Engines for Mobile Zero Emission Power (CEMZEP) programme, pumps liquid nitrogen (LiN) from the tank – mounted underneath the refrigerated trailer – through a heat exchanger where it provides cooling.

... to continue reading you must be subscribed

![02_Dearman-Hubbard-zero-emission-nosemount-TRU[1]](https://www.gasworld.com/cdn-cgi/image/width=231,height=130,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/02_dearmanhubbardzeroemissionnosemounttru1_717835.jpg)

![02_Dearman-Hubbard-zero-emission-nosemount-TRU[1]](https://www.gasworld.com/cdn-cgi/image/width=462,height=260,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/02_dearmanhubbardzeroemissionnosemounttru1_717835.jpg)

![Dearman_Air-Products-Refueler[2]](https://www.gasworld.com/cdn-cgi/image/width=231,height=130,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/dearman_airproductsrefueler2_381738.jpg)

![Dearman_Air-Products-Refueler[2]](https://www.gasworld.com/cdn-cgi/image/width=462,height=260,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/dearman_airproductsrefueler2_381738.jpg)