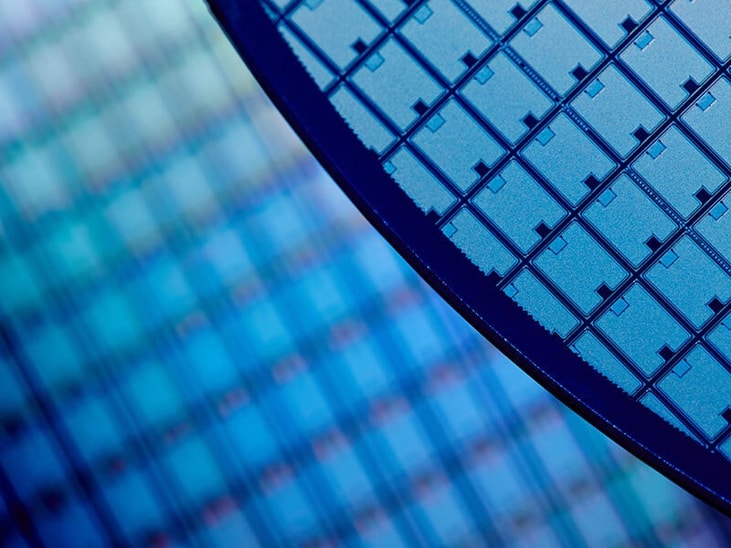

Japan: Demand for both silicon wafers and argon on the road to recovery

Having been ‘very sluggish’ for quite some time, the demand for silicon wafers (monocrystalline) in Japan is now firmly on the road to recovery, according to The Gas Review (TGR).

Demand for argon is also believed to be recovering as a result, approaching an annual level of 40 million m3.

Statistics from the Japan Society of Newer Metals demonstrate that production of monocrystalline silicon in January 2014 amounted to 8,051 tonnes, a growth of 27% over the previous year, while the level of exports rose from 51% in 2013 to 54% in 2014. The depreciation of the yen and the health of the semiconductor sector were cited as the reasons for such growth.

This is reaffirmed by data from the Ministry of Economy, Trade and Industry (METI) for 2014, with its information suggesting that the production of silicon wafers amounted to 4.6 billion, a growth of 38%, and shipments reached 4.9 billion – a growth of 32%. This is still at a lower level than the market peak of 2010, but it is a clear break from the well-documented slump of 2013.

... to continue reading you must be subscribed