Record orders for InvenSor

According to a new future study by BP Energy Outlook, global energy demand is set to increase by up to 41% by 2035. This is primarily due to rising demand in emerging nations like China and India.

Chillers and air conditioners still make up a very large proportion of this total energy consumption; in Germany, for example, they account for around 15% of total end-use electricity consumption.

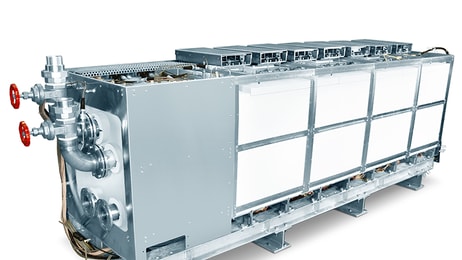

For this reason, there have long been efforts by governments to promote the procurement of energy-saving chillers. Adsorption chillers are now making an increasing contribution to improving the energy efficiency of chillers and air conditioners. German companies like InvenSor GmbH, with offices in Berlin and Lutherstadt Wittenberg, are pushing this development.

What’s unique about the multi-award-winning InvenSor chillers is that they are powered by waste heat rather than electricity. Additionally they also help the environment by using pure water as a refrigerant.

... to continue reading you must be subscribed