Finding the leak that threatens the proverbial ship

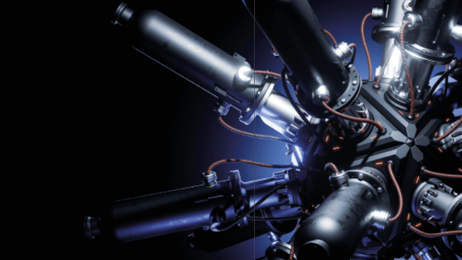

Unintended leaks of gases or vapours from pressurised industrial equipment can be extremely hazardous to workers, the community, and the environment, as well as contributing to lost and unaccounted for (LAUF) product.

Faulty pieces of equipment – especially valves and connectors – are frequently to blame, and even a small discharge can add up to dangerous levels of volatile air pollutants. Consequently, governments worldwide have tightened regulations, requiring industries to implement leak detection and repair (LDAR) programmes to monitor, analyse and reduce the volume of hazardous gases escaping into the environment.

The oil and gas industry is heavily regulated by numerous official bodies to ensure pipelines run efficiently and safely. In the US, this includes the Federal Energy Regulatory Commission and the Environmental Protection Agency, with the latter requiring LDAR programmes for many types of facilities. Similarly, operators in Europe must comply with Standard EN 15446:2008: Fugitive and diffuse emissions of common concern to industry sectors – Measurement of fugitive emission of vapors generating from equipment and piping leaks.

... to continue reading you must be subscribed