The science behind the cold box

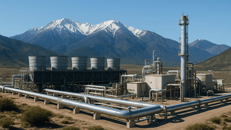

Today, China’s market is demanding mega-size and multi-train ASUs for coal-to-liquid (CTL) applications. After the success of its mega ASU Project in Qatar, Linde can now present another success in building multi-train ASUs near Yinchuan City, in the middle west of China, for CTL application.

The kick-off meeting for the project took place in March 2013. Six trains were designed for the supply of 630,000 Nm³/h of high pressure oxygen for the Shenhua Ningxia Coal-to-Liquid Project. To supply this big oxygen flow cost-effectively, reliably and safely, Linde Engineering chose a robust process based upon the very latest plant design principles. This comprises internal compression for the high pressure oxygen and nitrogen product, and uses an air booster process with high energy efficiency.

To be able to supply the equipment to the remote site, the maximum diameter for the vessels was limited to 4.8m. Based upon this condition, and the target to save energy for compressing process air, a process with a low air factor was selected. The endorsed process cycle uses a crude argon column, which only takes out the argon from the main rectification in the low pressure column in order to increase the oxygen yield. The argon itself is not used, but blown into the waste nitrogen. With this approach a low energy consumption is achieved, because less air is needed to produce the required oxygen product. The lower air load allows to keep the column diameters below 4.8m.

... to continue reading you must be subscribed