Mehrer Compression

Mehrer Compression GmbH is one of the leading manufacturers of oil-free piston and diaphragm compressors worldwide. For 130 years the company from Southern Germany has been setting standards in gas and air compression.

Due to its failsafe, efficient and absolutely oil-free compressors, Mehrer Compression GmbH is a renowned partner for the process engineering industry, the process gas industry, as well as in the energy and environmental sector.

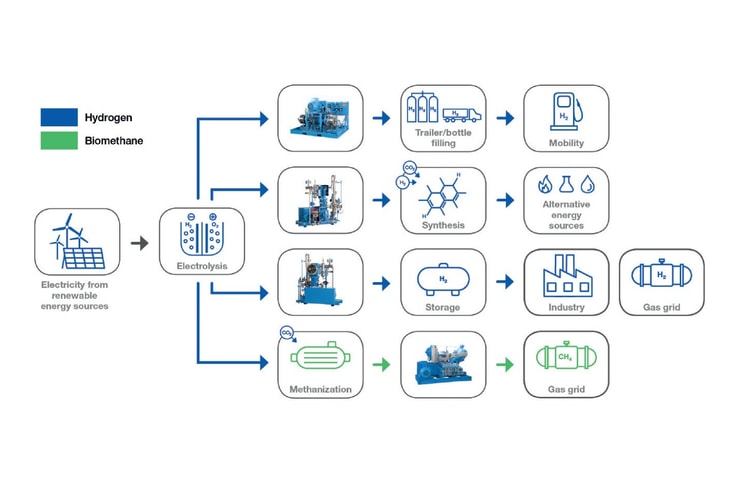

Tomorrow’s energy at high pressure

... to continue reading you must be subscribed