Get to know biogas

Atlas Copco breaks down biogas and its potential for gasworld readers in this article, explaining how its compressors, oxygen generators, blowers, vacuum pumps and industrial chillers are utilized in turning waste into green energy. Atlas Copco has a RNG compressor rebuild shop in Dallas and packages systems in Houston.

What do we mean by biogas?

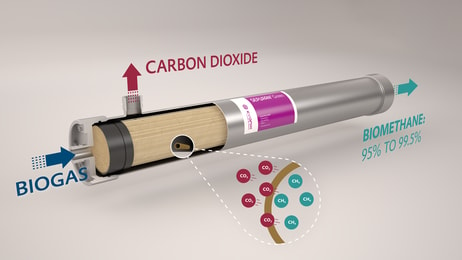

David Walters, CNG/RNG National Sales Manager – North America, Atlas Copco (DW): Biogas is the captured gas that comes naturally from the anaerobic digestion of raw materials such as agricultural waste, manure, municipal waste, plant material, sewage, or food waste. Anaerobic digestion is a sequence of processes by which microorganisms break down biodegradable material in the absence of oxygen – on an industrial level specialized digesters are used to control and manage the process. Biogas is a mixture of gases, primarily consisting of methane and carbon dioxide, along with traces of other gases. It is classed as a renewable energy source.

... to continue reading you must be subscribed