Harris, McKinney rapidly respond with oxygen regulators for NYC hospitals

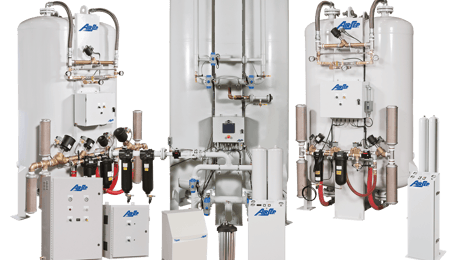

Harris Products and McKinney Welding Supply collaborated to rapidly provide oxygen regulators and systems at two New York City field hospitals.

As McKinney rushed to respond to the urgent need for oxygen delivery systems, the New York-based distributor turned to Harris for custom solutions at the field hospitals.

The temporary hospitals at the Billie Jean King National Tennis Center and at the Brooklyn Cruise Terminal were set up to treat coronavirus (Covid-19) patients.

... to continue reading you must be subscribed