Huntingdon Fusion Technologies introduces the PurgEye® 1000

Huntingdon Fusion Techniques HFT® has introduced the PurgEye® 1000, a localised sensor with a long-distance cable. The new release displays the oxygen level in the welding zone on the Weld Purge Monitor® screen from 10, 50 or even 1,000 meters away from the weld.

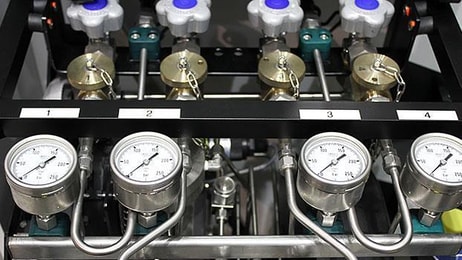

The PurgEye® 1000 comprises a stainless steel housing with a sensing head that can be fitted onto any Pipe Weld Purging System or left in the welding zone and have the oxygen levels transmitted electronically to a monitor up to 1km away.

“By using a remote sensing head, which can be fitted onto any Mechanical or Inflatable Tube and Pipe Welding Purging System from 1” diameter upwards, or even left in the welding zone, the oxygen level can then be measured directly at the weld location and the information will be electronically transferred to the monitor up to 1km away,” said Luke Keane, Technical Sales Manager for HFT®.

... to continue reading you must be subscribed