Huntingdon Fusion Techniques launches updated PurgEye® 1000 Weld Purge Monitor

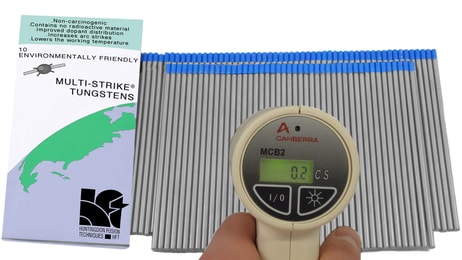

Huntingdon Fusion Techniques (HFT®), a weld purging products manufacturer, has launched an updated version of its PurgEye® 1000 Weld Purge Monitor, which enables operators to read weld purge gas levels from a distance.

The updated device makes it possible to immediately read gas levels from the underside of the welding joint from up to 1,000 metres away.

The sensor is secured and fixed inside the purging system itself, which is connected to the measuring instrument via a data cable. The purge reading is then sent back to the instrument instantly allowing operators to accurately monitor, and therefore avoid oxidation, of weld zones.

... to continue reading you must be subscribed