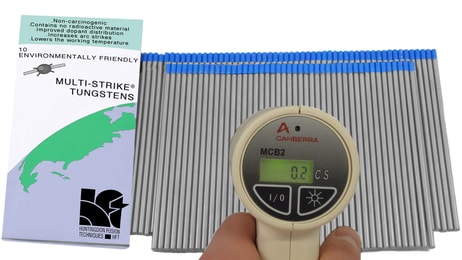

Huntingdon Fusion Techniques updates PurgEye 200 monitor

Huntingdon Fusion Techniques (HFT®) has launched an updated hand-held PurgEye® 200 Weld Purge Monitor®, now with PurgeNet™.

The portable device has an OLED (organic light emitting diode) display, which the company says will give brighter, clearer and sharper readings for viewing at greater distances than before and at wider angles.

The PurgEye 200 can operate from either long life rechargeable batteries or mains power.

... to continue reading you must be subscribed