HFT’s latest oxygen analyser now launched

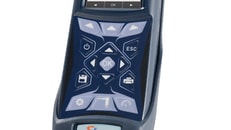

Huntingdon Fusion Techniques (HFT) has now released its new ‘virtually non-destructible’ PurgEye® Site device as part of its Weld Purge Monitor® range.

The UK-based business first gave the industry a sneak peek at its new onsite oxygen (O2) analyser at Fabtech in November 2016. Now, the PurgEye Site has been released and is fully available throughout the US from COB Industries Inc.

The handheld, portable device measures O2 levels from 1,000 parts per minute (ppm) down to 1 ppm and is housed in a secure, safe, waterproof and dustproof box.

... to continue reading you must be subscribed

![Dearman_Air-Products-Refueler[2]](https://www.gasworld.com/cdn-cgi/image/width=231,height=130,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/dearman_airproductsrefueler2_381738.jpg)

![Dearman_Air-Products-Refueler[2]](https://www.gasworld.com/cdn-cgi/image/width=462,height=260,fit=cover,quality=90,metadata=none,format=auto,gravity=auto/https://www.gasworld.com/wp-content/files/gwml/dearman_airproductsrefueler2_381738.jpg)