HFT’s pipe purging systems resist 760ºC

Huntingdon Fusion Techniques (HFT®) now manufactures Argweld® quick purge systems with glass treated silicone cloth that can resist temperatures up to 760ºC.

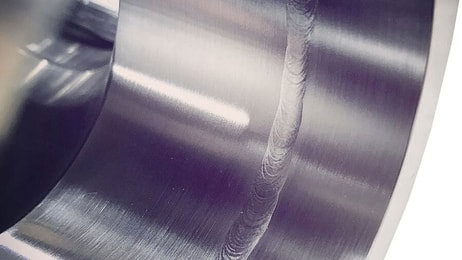

High strength steel joints must be pre-heated prior to welding and also require a post-weld heat treatment. Weld joints of this nature are often purged of oxygen and welded in an inert atmosphere to reduce the risk of ‘sugaring’, an imperfection that could allow metal pieces to break off inside pipework and cause damage to turbines.

HotPurge® has been developed by HFT, as an Inflatable pipe purging system for heat treated chrome and high strength stainless steel pipe joints where temperatures can reach 760ºC (1,400ºF) for many hours.

... to continue reading you must be subscribed