HFT’s new PurgEye 300 Nano reads down to 1 ppm

To keep-up with constant upward trends in quality control procedures, Huntingdon Fusion Techniques (HFT®) have now developed the PurgEye® 300 Nano, an entry level, low cost Weld Purging Monitor®, that reads down to 1 ppm, especially for the Process Industries.

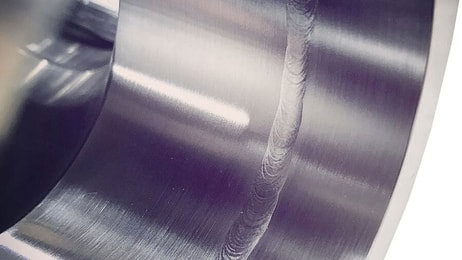

A customer in the UK recently said, “The PurgEye Nano is really easy to use, with excellent results. The company, which trains TIG welders on stainless steel pipes, enjoys great benefit using it. Previously, each welder would let his inert argon flow as much as possible before starting to weld, to be sure that purging was sufficient. With the PurgEye 300 Nano they know when to reduce the argon flow prior to welding and in such a way they save a significant amount of expensive argon. Now there is no guessing! Any welders and their assistants can use the Nano after only a few minutes of receiving the instructions.”

The PurgEye Nano has been developed for weld purging where data logging, alarms and welder control are not necessarily required. It is small, lightweight and inexpensive. Developed with a unique long life sensor that has the capacity to measure oxygen down to 1 ppm (accurate to 10 ppm), boasting a sensor warm up time under 60 seconds.

... to continue reading you must be subscribed