HFT has updated the PurgEye® 200 Weld Purge Monitor®

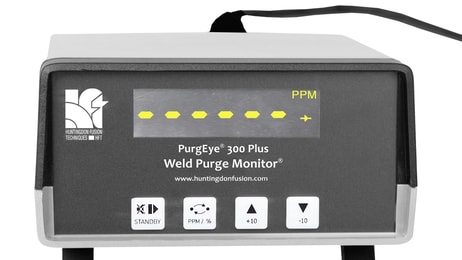

HFT® launch an updated hand-held PurgEye 200 Weld Purge Monitor, now with PurgeNet™.

Georgia Gascoyne, CEO for HFT, said, “PurgeNet™ allows networking to standard accessories. Typically, one accessory allows direct interface to an Orbital Welder or any other automatic welding machine, so that the oxygen (O2) level in the vicinity of the weld can be monitored and the welding machine can be switched on or off according to pre-set O2 levels. A second accessory is a warning lamp that can signal when O2 levels are low and high according to pre-set levels.”

... to continue reading you must be subscribed