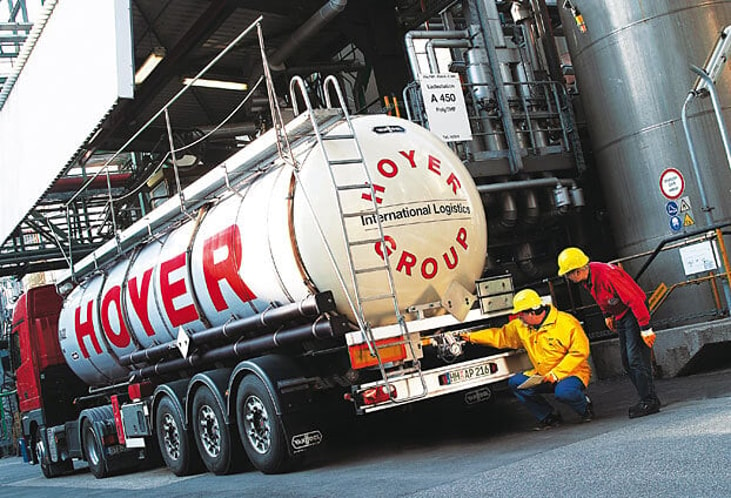

HOYER upgrades entire gas tank container fleet with telematics logistics system

Logistics company HOYER is upgrading its entire tank container fleet with a new, state-of-the-art telematics system.

The system is described by the Hamburg-based business as the ‘next stage in worldwide logistics management,’ offering solutions to control, monitor, analyse and optimise logistical processes, saving costs and improving the existing fleet’s utilisation.

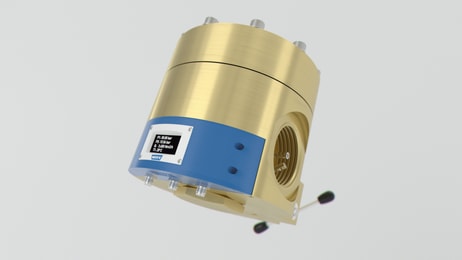

The new Smart Logistics telematics system monitors the pressure, temperature, filling level and density parameters of Hoyer’s goods in transit, as well as general geographic location.

... to continue reading you must be subscribed