Huntingdon Fusion Techniques expands flexible welding enclosures range

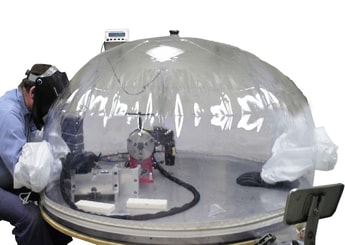

Huntingdon Fusion Techniques (HFT®) has broadened its Flexible Welding Enclosures® range to include purpose designed and manufactured models to meet the needs of research and production entities internationally.

The UK-based business says the ultraviolet stabilised, transparent, low vapour pressure polymer used for these enclosures, is tough and not easily damaged, but for those cases where damage may occur, a repair kit is included with all enclosures as they are shipped, with extra kits assembled and shipped on a next day delivery process if ever required.

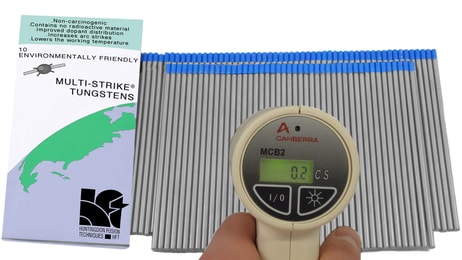

In a press release, the company said, “These purpose designed enclosures have leaktight zips placed anywhere that they may be required for access and entry points. Argon (Ar) entry points are placed at floor level as is good practice for purging with Ar with matching volume exhaust points at the top. Additional valved ports are available for adding Weld Purge Monitors® to inform the users when welding is safe to start to avoid risk of oxidation of the deposited material.”

... to continue reading you must be subscribed