Hydrogen plant utilising TechnipFMC technology in full operation

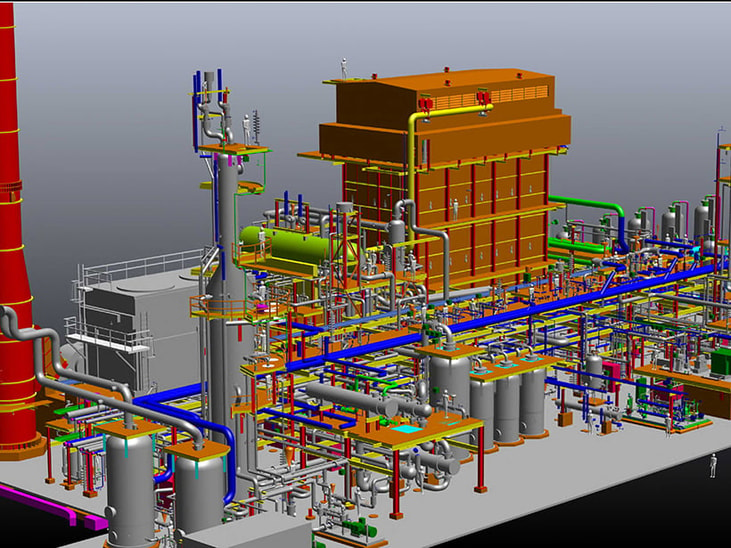

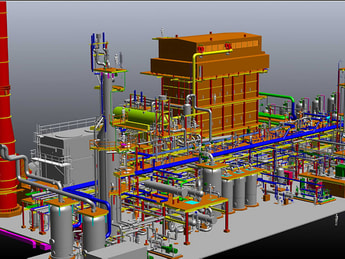

A grassroots hydrogen (H2) plant in Montana, US, utilising TechnipFMC technology went into full operation last month.

In November 2015, TechnipFMC announced it had been awarded a significant contract by CHS Inc., a US-based global agribusiness, to provide proprietary technology and engineering, procurement and construction for the 40 million standard cubic feet-per-day H2 plant, located at the CHS refinery in Laurel.

The plant’s design will utilise Technip FMC’s high efficiency top-fired steam reforming technology to produce high purity hydrogen (H2) and export steam, as well as the latest nitrogen oxide (N2O) reduction technology to ensure minimum emissions.

... to continue reading you must be subscribed