Air Liquide, Coca-Cola inaugurate Californian hydrogen fleet

A year after Air Liquide Industrial U.S. LP revealed it was to supply liquid hydrogen, filling stations and infrastructure to power a fleet of forklift vehicles at Coca-Cola’s site in California, the two companies have now held a ‘green ribbon cutting’ inauguration ceremony.

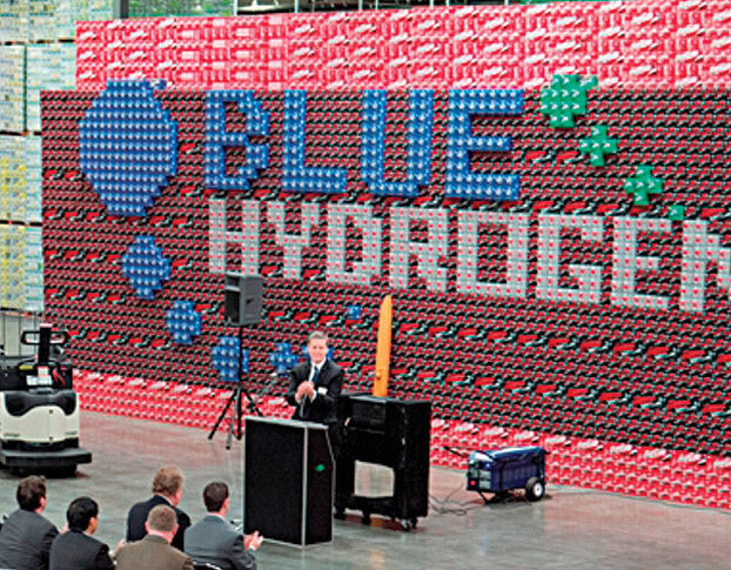

The event, hosted by Coca-Cola at its bottling and distribution centre in San Leandro, California, was held to inaugurate the fleet of Air Liquide’s hydrogen-powered forklifts.

Speaking in front of a colourful mosaic wall of soft drink cases arranged to spell ‘Blue Hydrogen’ and ‘Live Positively’ the President of Air Liquide Industrial U.S., Mark Lostak, commended Coca-Cola for its commitment to sustainability and carbon emission reduction.

... to continue reading you must be subscribed